According to the latest news, we only have one planet so let’s take care of it!

Our commitment is at the heart of all our decisions: Reduce our carbon footprint by 1/3 by 2026 to contribute to carbon neutrality by 2050 and actively contribute to several Sustainable Development Goals set by the UN, namely:

More effort for less carbon. Manufacturing generates carbon emissions and we are well aware of this. So, in order to make our products as green as possible, there is only one solution: Never give up and start rolling up our sleeves!

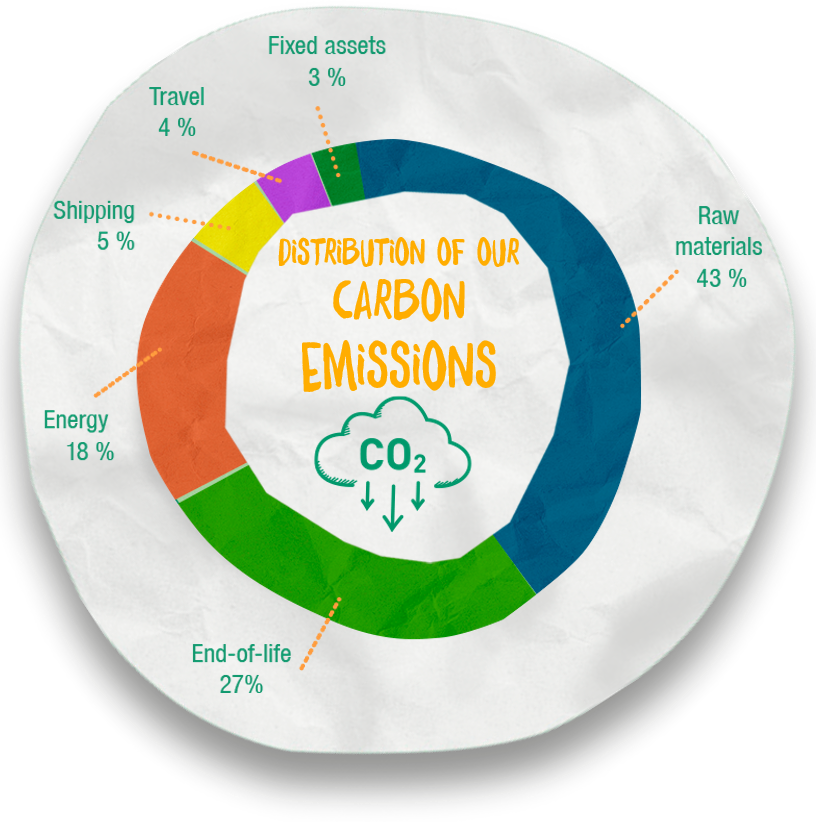

The Maped Group’s carbon footprint in 2018 was: 80,340 tonnes of CO2

What does this represent?

- The combustion of 182,800 barrels of oil

- 9300 plane trips around the world

- The annual carbon footprint of 7,650 residents in France

Let’s re-invent our product

70% of our emissions are generated by our products. So the best way to change tomorrow is to start with designing them better.

What is eco-design at Maped?

It is taking the environment into account at every stage of a product’s life cycle.

We seek to reduce the impact of our choices in terms of materials used, production processes, including anticipating the end of the product’s life. So we continuously learn about new processes, we draft guidelines, always choose the solution that will have the least impact.

For example with FSCTM-certified materials from responsibly managed sources: Like our coloured and graphite pencils and rubber erasers (FSC-C156374 | www.fsc.org).

- The rules for using the FSC trademark are very strict, defined by specific FSC standards. Inside the Group, only FSC certified subsidiaries are able to offer and sell FSC certified products.

- Maped SAS FSC certificate

Let’s re-invent our packaging

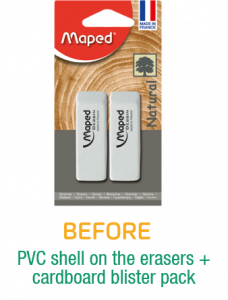

Recyclable packaging for a more sustainable world! Elimination of all PVC packaging in 2022!

Get rid of the excess, for example: paper packaging is much lighter for our erasers.

BEFORE: PVC shell on the erasers + cardboard blister pack.

AFTER: 100% recyclable paper packaging. Representing 6.2 tonnes of packaging saved in 2 years and representing 14.1 tonnes of PVC saved in 2 years.

Re-invent the way we produce

More robust industrial devices

For example, the moulds that make our felt-tip pens are super robust and can produce hundreds of millions of units.

Less energy and more sustainability

Our factory in France has been powered by 100% green electricity since 2020, mainly through hydroelectricity. The result? Our carbon impact due to electricity is divided by 10!

Our German site is ISO 50001 certified and has invested in the renewal of its industrial tools in 2019.

The result? -25% energy consumption.

Protecting and recycling water

In China, a system was installed in 2020 to recycle cleaning water.

This system allows for a zero waste closed circuit because no dirty water is discharged.

Optimised logistics flows low-carbon transport and local procurement

In France, since the beginning of 2020, 100% of our inter-site shuttles will be powered by biogas. And that represents

75% of CO2 emissions saved!